The automobile industry is undergoing a seismic shift, thanks in large part to the introduction of laser-cutting technology. This high-tech tool has revolutionized how cars are made, allowing automakers to create vehicles with greater precision and accuracy than ever before.

Despite its relatively recent introduction into the automotive industry, laser cutting is already proving to be an invaluable asset for many leading carmakers – one which could shape the future of vehicle production for years to come.

This article will provide an overview of how laser cutting works in the automotive industry, its advantages over traditional techniques, and some of its applications within the production line.

Introduction to Laser Cutting in Automobile Manufacturing

Source: issuu.com

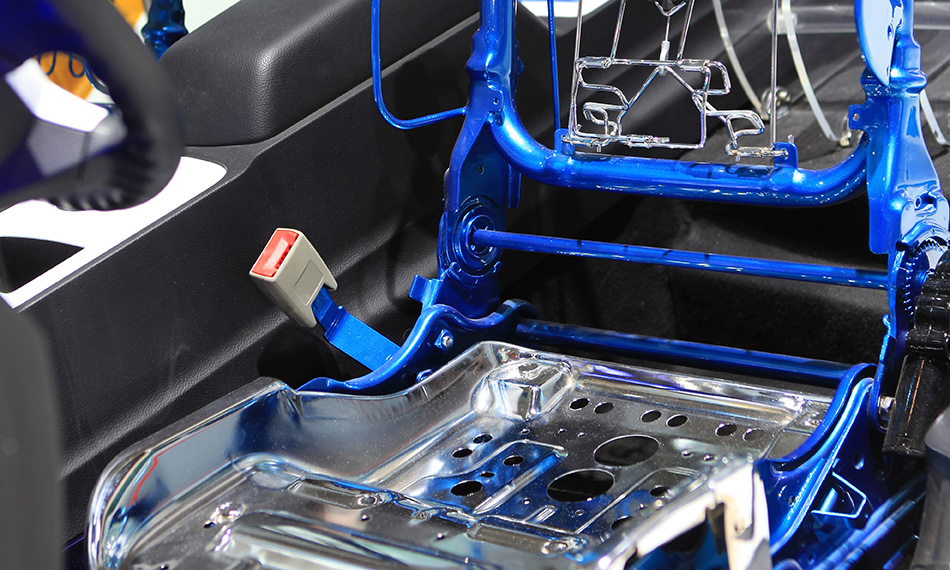

The introduction of laser cutting to automobile manufacturing has revolutionized the industry and changed the way cars are constructed. Laser cutting is a precise and efficient method for creating complex car parts from metal sheets.

It requires no tooling or manual labor, making it faster than traditional machining methods. The process involves using a powerful laser beam to cut through metal with incredible accuracy, leaving little need for post-processing or finishing touches.

Additionally, we will discuss why this technology has become so popular among manufacturers worldwide as well as how it is influencing other aspects of vehicle design such as safety features and environmental sustainability efforts.

Adoption of Laser Technology by Major Auto Manufacturers

Source: www.canadianmetalworking.com

The adoption of laser technology by major auto manufacturers is revolutionizing the automotive industry. With laser cutting, automakers can produce more complex parts and components with greater precision than ever before.

Laser technology offers automakers a range of benefits, from enhanced production speeds to cost savings compared to traditional manufacturing techniques. By using lasers for cutting metal materials, auto manufacturers can reduce waste while increasing accuracy and efficiency in their production lines.

In addition, many companies are also utilizing laser marking and engraving as a means of branding or providing unique identifiers on their products. Automakers have found that laser technology is an invaluable tool when it comes to creating custom parts and components for their vehicles—allowing them to create complex designs quickly and accurately without sacrificing quality or appearance.

As such, the adoption of laser technology by major auto manufacturers has been instrumental in driving innovation within the automobile industry over the past several years.

Challenges with Applying Lasers to Car Assembly Lines

The use of lasers in car assembly lines has opened a new world of possibilities for the automobile industry, but it also presents its own set of challenges. One such challenge is that laser cutting requires high levels of precision and accuracy to ensure proper cuts are made with minimal waste or damage.

Assembling a car with these precise parts can be difficult as the pieces must fit together perfectly; misalignments can lead to costly repair work down the line. Additionally, using lasers to create complex shapes and curves requires special skills and careful calibration which adds additional cost and complexity to the process.

Furthermore, when using lasers in an assembly line setting, safety precautions must be taken into account due to potential hazards associated with powerful laser beams including light reflections that could cause eye damage or other complications.

Finally, depending on the type of material used there may need to be additional steps taken before laser cutting such as pre-treatments like coating removal or surface cleaning that add further time constraints to the manufacturing process.

Source: www.coherent.com

Conclusion

The automobile industry has experienced a revolution in recent years, thanks to the introduction of laser cutting. Steel is one of the most important materials used in car manufacturing and laser cutting has allowed for precision cuts that would have previously been impossible.

It has enabled faster production times, higher-quality finishes, and cost-effective solutions. The Best laser cutting machines feature advanced technology to help manufacturers produce better vehicles at lower costs. All these factors mean that laser cutting will continue to be an integral part of car manufacturing going ahead into the future.