The automotive sector is a major driver of innovation and efficiency, and laser cutting machines are an integral part of achieving this. By leveraging precision technology, laser cutting machines enable the production of parts with exceptional accuracy at high speeds.

This article will explore the role these machines play in driving efficiency in the automotive industry and how they are making significant contributions to modern manufacturing processes.

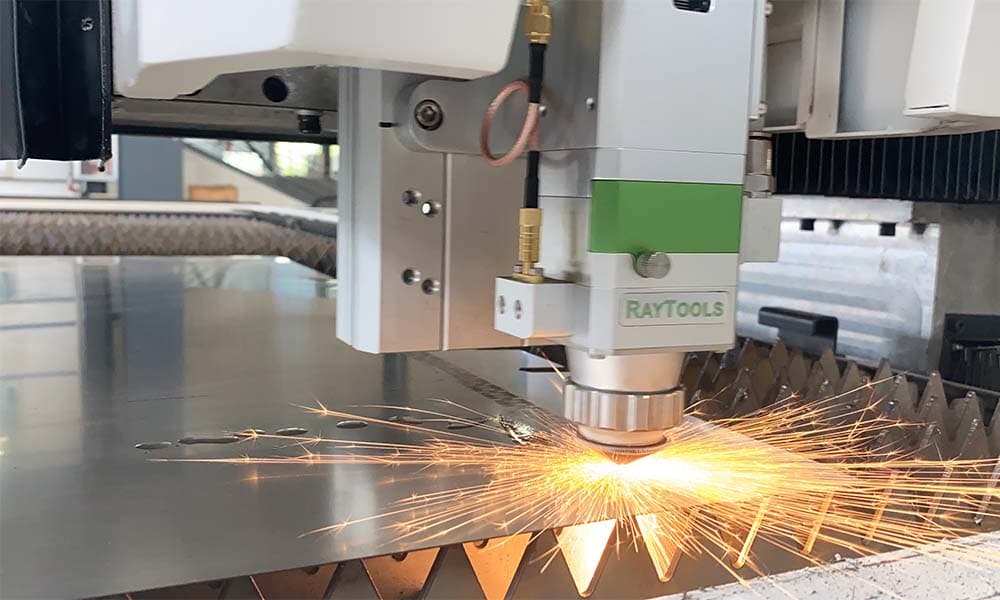

Increase Efficiency with Laser Cutting Machines in Automotive Manufacturing

Source: www.thefabricator.com

The automotive sector is constantly seeking new and innovative ways to boost efficiency and productivity. Laser cutting machines are one such tool that can drastically improve the manufacturing process.

By using laser-cutting technology, automotive manufacturers can automate parts production with greater precision than ever before. This increased accuracy eliminates costly mistakes while also allowing for faster production times.

Additionally, laser-cut parts require fewer finishing steps, further reducing time and cost. All of these benefits come together to create a more efficient and profitable environment for automotive manufacturing businesses. With the help of laser cutting machines, automotive manufacturers are able to reduce material waste by precisely creating components that fit their exact specifications.

Moreover, they no longer need to worry about meeting tight tolerances when it comes to part fabrication as the lasers used in these machines are capable of producing highly accurate cuts every single time; this removes any margin of error from the equation entirely!

Finally, because this technology is so precise it also reduces labor costs associated with manual machining processes since less manpower is needed for each individual part produced on a laser machine.

Overall, utilizing cutting-edge technologies like laser cutting has revolutionized how we approach manufacturing within the automotive sector; businesses now have access to tools which allow them increase efficiency while simultaneously driving down costs and improving product quality at unprecedented levels!

Enhancing Automotive Production with Laser Cutting Technology

Source: www.thefabricator.com

Laser cutting machines are revolutionizing the automotive industry, providing a high-speed and cost-effective method for producing complex parts. By introducing laser cutting technology into production processes, factories can increase capacity while improving accuracy and precision.

Laser cutters enable manufacturers to produce components quickly with minimal waste, reducing labor costs and increasing productivity. The introduction of laser cutting machines also minimizes the need for manual intervention in the production line, resulting in improved product quality assurance and reduced risk of human error.

With their ability to cut intricate shapes from almost any material with precision, lasers have become an invaluable tool for carmakers looking to enhance efficiency and reduce costs. Furthermore, laser technology can be used to cut materials that require greater strength or durability than traditional methods such as stamping or sawing might offer—allowing automotive companies to create more innovative designs without compromising on quality or performance.

From simpler tasks like trimming edges of sheet metal panels to complex operations like forming holes into parts for assembly purposes; laser cutting is becoming increasingly important in driving efficiency across all aspects of carmaking today

The Impact of Laser Cutting on Automotive Production Times and Quality

Source: www.thefabricator.com

The utilization of laser cutting machines in the automotive sector has revolutionized production times and quality. Laser cutters offer a precise, efficient means of manufacturing parts, resulting in improved results for both cost and time reduction.

Compared to traditional mechanical methods, the accuracy with which these machines can produce car components is far superior. Furthermore, since no contact between tool and material is required during cutting processes, there are fewer chances of errors or mistakes being made that would otherwise detract from product performance or reliability.

These enhanced capabilities have allowed automakers to reduce production times significantly while still achieving higher standards of quality control when it comes to manufactured parts. Additionally, the use of laser cutters has enabled more intricate designs to be achieved compared to what was previously possible using conventional methods.

This opens up more possibilities for creative design processes that can create new opportunities for car manufacturers as well as their customers who will benefit from increased customization options when buying vehicles.

Overall, the impact that laser cutting technology has had on automotive production times and quality cannot be overstated; this advancement provides an effective solution for companies looking to drive efficiency while still producing high-quality parts at competitive prices.

Conclusion

Source: www.laser-cutting-ipg.com

The use of laser cutting machines in the automotive sector is revolutionizing the way vehicles are produced. Laser cutting has proven to be an important part of driving efficiency, as it offers superior precision and accuracy when it comes to components production.

With a range of applications from sheet metal fabrication to 3D engraving, laser cutters have become a valuable asset for many car manufacturers worldwide.

Thunder Lasers top-of-the-line laser cutting systems provide the utmost accuracy and quality that makes them ideal for any automotive operation looking to streamline their manufacturing processes while producing high-quality parts efficiently. Ultimately, the use of laser cutters can help automakers produce more efficient cars with higher quality components at lower costs.