The rotary revolution is an exciting exploration of the cutting-edge advancements in screw air compressor technology. From powerful motors to energy efficient and reliable systems, this modern technology has been growing rapidly over the last few decades.

As organizations strive for more efficient operations, air compressors have become essential tools for meeting their goals. This article delves into the latest developments in this field and outlines how they are being used to improve productivity, reduce waste, and create a cleaner environment.

It will also provide readers with an understanding of why these advances are so important in todays world. With its groundbreaking innovations, this revolutionary form of power is transforming our lives for the better – paving the way towards a brighter future.

Understanding the Benefits of Rotary Revolution Technology

Source: iselinc.com

Rotary Revolution technology is a groundbreaking advancement in screw air compressor technology. It has revolutionized the way businesses operate and can provide numerous benefits to those who use it.

With Rotary Revolution, energy efficiency is increased, maintenance costs are decreased, and production times are reduced significantly. This new technology also allows for more consistent product quality due to its ability to maintain uniform pressure levels throughout an operation.

Additionally, this cutting-edge technology also offers improved safety features such as automated shutoff systems that will help protect workers from potential hazards associated with industrial machinery and processes. Understanding the advantages of Rotary Revolution Technology is essential for companies looking to take advantage of this powerful tool in order to ensure they remain competitive in today’s market.

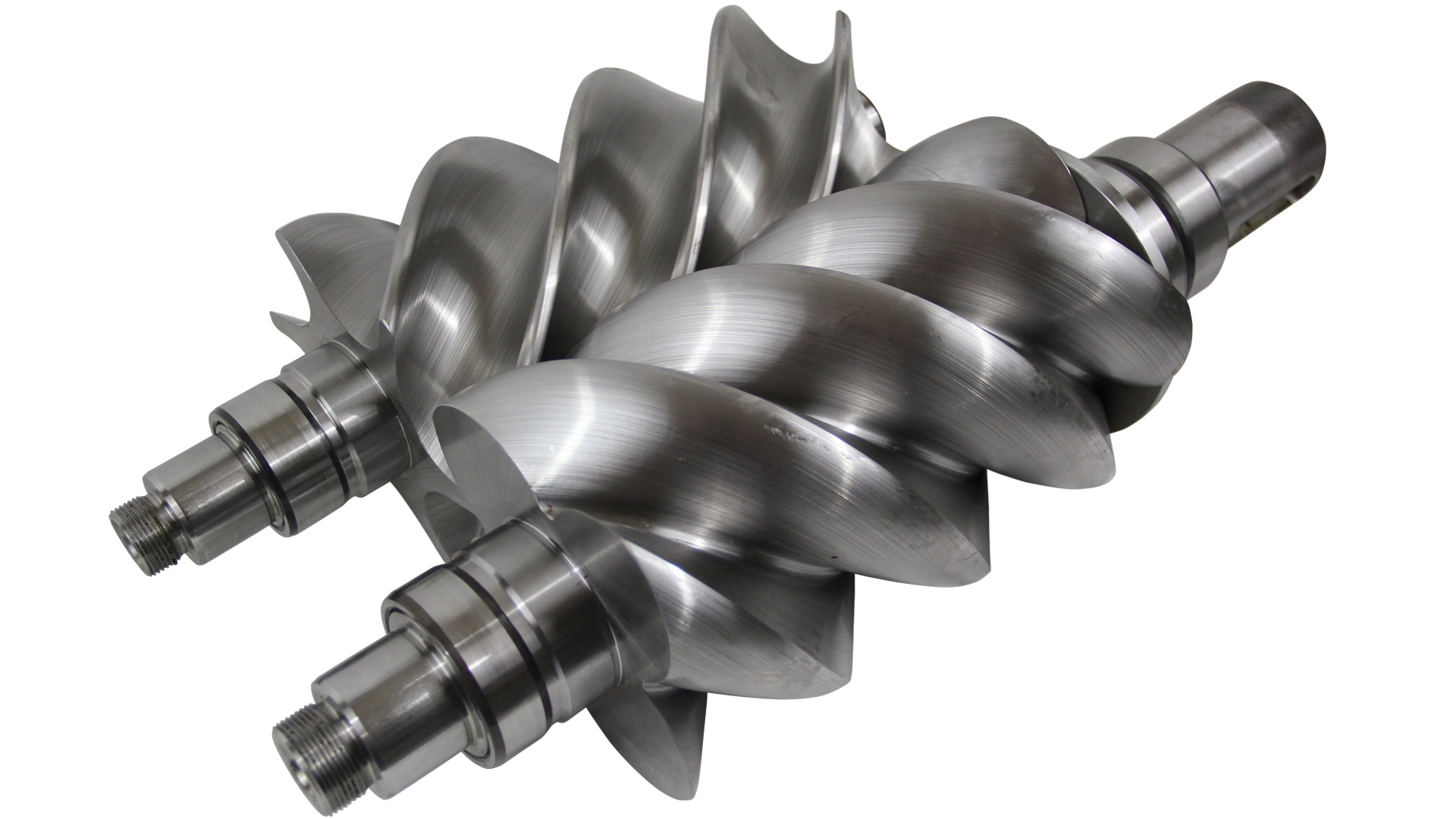

Exploring the Latest Innovations in Screw Air Compressor Design

The latest innovations in screw air compressor design are revolutionizing the entire industry, ushering in a new era of efficiency and productivity. With advancements to both rotary and centrifugal technology, these compressors can now handle more demanding jobs with greater force and accuracy than ever before.

Rotor blades have been redesigned to deliver increased air volume while maintaining high-pressure levels; this reduces energy consumption and noise pollution from traditional models. Advanced materials such as titanium alloys allow for lighter-weight designs that are still resistant to corrosion.

Additionally, electronic control systems offer users precise monitoring capabilities so they can adjust settings on-the-fly without having to shut down operations entirely. The result is a highly efficient system that provides maximum performance with minimal downtime.

From large industrial applications to smaller domestic uses, the latest advances in screw air compressor technology make it easier than ever before for businesses and individuals alike to get the job done faster and better than ever before!

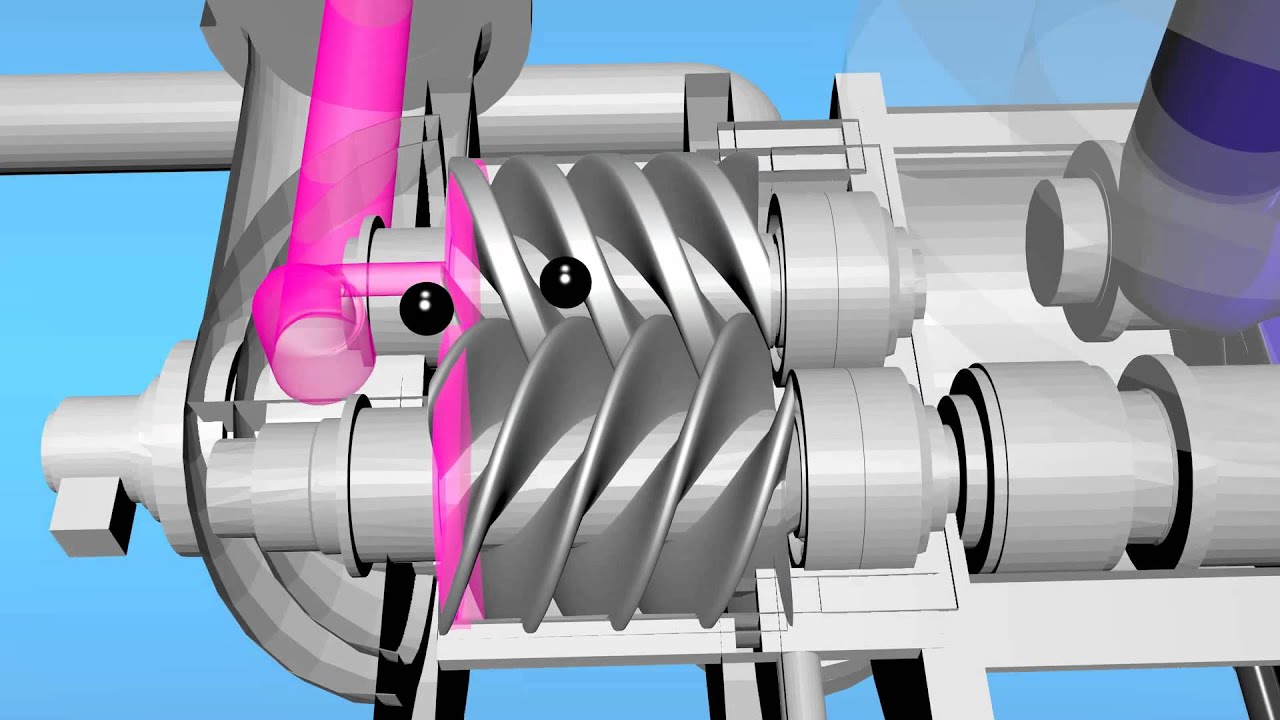

How Rotary Revolution Improves Performance and Efficiency

Source: youtube.com

Rotary Revolution has revolutionized the way screw air compressor technology is used in industrial and commercial operations. This revolutionary innovation has improved performance and efficiency significantly, while also reducing costs for businesses.

It is equipped with advanced features such as high-efficiency motor control that ensures a smooth running operation, increased torque from its rotors which drives more power to the compressor screws, and low vibration levels that helps reduce noise pollution. Additionally, its compact design allows it to be installed in tight spaces where other similar compressors may not fit.

The most impressive aspect of the Rotary Revolution is how it optimizes performance without compromising on efficiency. Its systems are designed to work together seamlessly so that every component works at its peak level of capacity – taking full advantage of available energy sources – resulting in greater productivity and precision with each operation.

Conclusion

In conclusion, the advancements in screw air compressor technology have revolutionized rotary compression and changed the way we use air compressors today. The development of sophisticated designs has enabled a more efficient and powerful performance than ever before.

With more research being conducted on Screw Air Compressor Design, there is no doubt that this technology will continue to evolve and provide us with countless opportunities for better solutions in industry applications.