A forklift is a heavy-duty machine designed to lift and transport loads. They are frequently utilized in distribution centers and warehouses. Many parts make up a forklift, each serving a different purpose. To keep your workplace safe, you need to understand how each piece works and what it does.

Drive Tires

Forklift tires are a critical part of your forklift’s performance. They absorb the weight of a heavy load and provide stability on uneven surfaces. They also help prevent injuries to your operator and the forklift itself. Proper tire maintenance can extend the lifespan of your forklift and reduce the cost of replacements. Forklift tires come in various types, from cushion to solid pneumatic. Understanding the characteristics of each type can help you make the best choice for your business needs. Fast moving Yale forklift products is an industry-leading manufacturer and provider of lift truck technology. Understanding the different components can help you to understand your machine and determine which parts need maintenance or repair.

Lift Handle

Source: blog.hyster.eu

Whether you’re a new or veteran forklift operator, it’s essential to know the various components of a forklift. The lift handle is the component that allows the forklift to lift and lower the load. It also provides a hold for the operator to control the operation.

Hydraulic Cylinders

Hydraulic cylinders are an essential part of many machines. They can extend the boom on an excavator, lift a blade or bucket off the ground, and tilt them forward or backward. A hydraulic cylinder contains a piston and rod that work together to manage and control the pressure inside. It also has sealed in and on the cylinder to prevent contaminants from mixing with the fluids inside.

Masts

Source: weldco-beales.com

Masts are the vertical structures on the front of a forklift that raise, lower, and tilt. Most masts are ‘three stages, ‘ meaning three channels are on each side, similar to I-beams. The mast can lift or tilt a load based on the hydraulic cylinders by pulling the mast lever in the cab. Some masts can lift the carriage without extending the mast channels, called “full free lift.” It is an excellent option for indoor applications where overhead space is limited.

Load Backrest

The load backrest is a rack-like extension that is bolted or welded to the carriage to prevent the load from shifting backward when the carriage is lifted to full height. Load backrests are required by OSHA standards to be fitted to any forklift that lifts loads over six inches above the overhead guard. They help to prevent objects from falling back onto operators. They are usually manufactured from heavy-duty steel framing to attach to the sides of the forklift’s carriage securely.

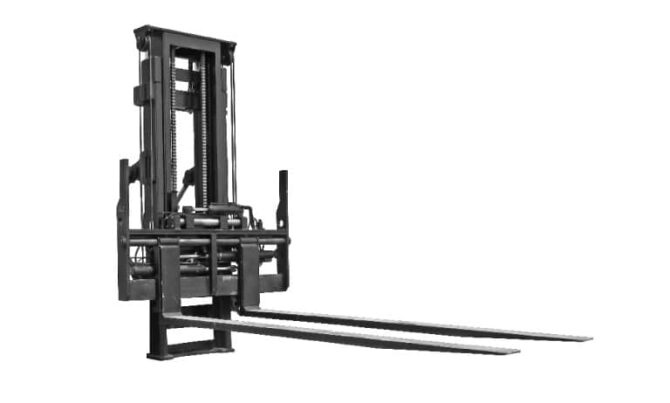

Forks

Source: tontio.com

Forks are the elongated parts of the forklift carriage that carry loads from the bottom. They come in various widths, lengths and shapes to match different applications. There are also fork types, like pallets, designed to fit a particular load precisely. Some forks even have a tilt cylinder that can be modified for different uses. Tilt cylinders are a crucial part of forklifts as they allow them to tilt the forks and carriage as the operator needs. It helps to ensure that the forks are at a proper angle when picking up or lowering the load.

Overhead Guard

Source: youtube.com

As one of the most versatile types of industrial equipment, a forklift can quickly and safely move loads between locations. Like the chassis of a car, a forklift’s truck frame is where many of its major components are attached to, including wheels and axels, engine, mast counterweight and overhead guard. Some forklifts also have fuel and hydraulic fluid tanks built directly onto their frame. The operator sits in the machine’s cab and controls it through the steering wheel, brake and acceleration pedals, tilt, lift and side shift levers, and a dashboard with gauges. Directly above the cab is an overhead guard, which protects the operator from falling objects or lousy weather.

Steer Tires

Tires are essential to any machine, and forklift tires are no exception. Properly maintained tires can save your company money and keep your employees safe. Several types of forklift tires exist, including pneumatic, solid and cushion. Each class is designed to work best for specific applications and environments.