Cars and other road vehicles are an inherent part of everyday life. They help people move from place to place faster. Also they ensure convenience and comfort.

But these vehicles won’t be so comfortable without the linear motion devices they feature. Linear actuators have many applications in the automotive industry, with several benefits. We’ll discuss these benefits in this post.

They Boost Performance

Source: automate.org

Thanks to linear actuators, many car parts work better. The motion devices boost performance by generating accurate linear movements for different tasks.

One good example is for vehicles with variable exhaust systems. Such systems need to adjust the exhaust flow to match the driving mode. And the shift in position is more accurate with a linear actuator. In addition, the actuator will produce less noise while operating.

Linear actuators further help improve the performance of car windshields and doors. This is true especially for automatic ones. These car parts need to slide and glide and change angles. A linear actuator ensures they are well positioned as the user wants.

Linear actuators also enhance the performance of braking systems. Manufacturers use motion devices to test the reliability level of such systems. Should there be errors, they address and fix them at once.

They Enhance the Well-being of Users

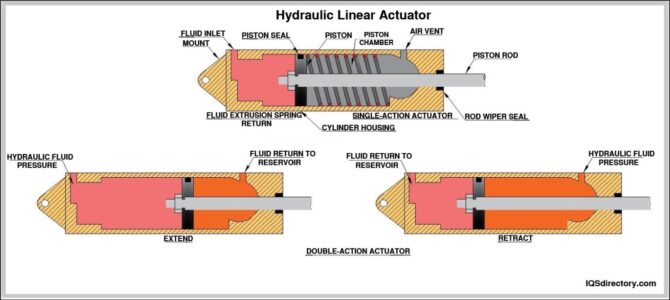

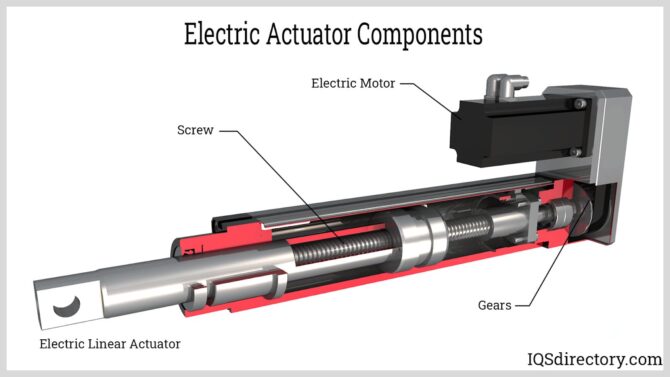

Source: iqsdirectory.com

As mentioned earlier, cars won’t be so convenient without linear actuators. One chief benefit of motion devices, then, is to ensure a smooth ride for all automotive users.

Most vehicles come with many ergonomic features. Some may even be for aesthetics. But, whether for functionality or style, these features depend on linear actuators to function.

While in the car, you can recline the seat to get a better resting position. You can also adjust the headrests and open the windows for proper ventilation. Linear actuators make all these easy. It seems common, but is still a notable advantage.

They Help Reduce Errors

Source: iqsdirectory.com

With manual operations, there’s always room for mistakes. But with automation, errors are less likely to happen. One way for automotive manufacturers to introduce automation is with actuators. The devices ensure each car part is well assembled and connected.

Above all, the motion device helps avoid mistakes in the engine and chassis. Consider the robotic welding process used to connect chassis and engine components. With linear actuators, manufacturers get better accuracy and consistency while making such connections.

Linear motion devices also help reduce errors by ensuring proper measurement of the car components. This usually involves checking reliability. Using linear actuators, manufacturers simulate tests to see how car components perform against different factors. Factors like pressure, loading, and corrosion, to name a few.

Conclusion

You’ll find many applications in the automotive industry that feature linear actuators. These actuators are more or less irreplaceable due to the critical role they play. And they bring in many benefits. In particular, they:

- Boost vehicles’ performance

- Improve the well-being of the users

- Help reduce errors via testing

Thanks to the above benefits, cars and other vehicles are more reliable.